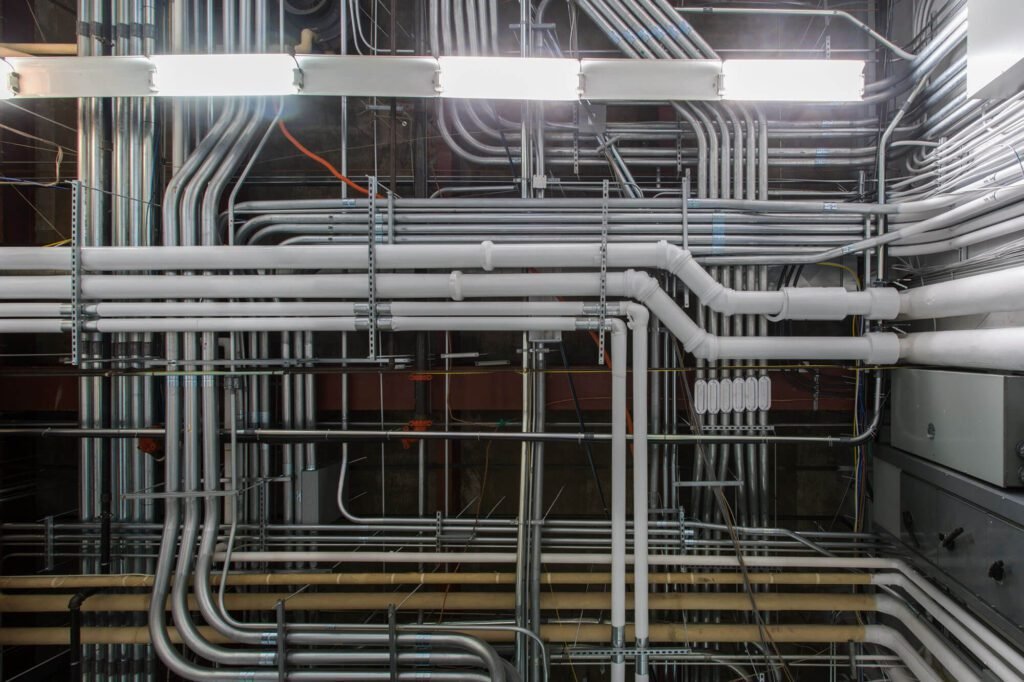

Conduit connectors are essential components in electrical systems, acting as a bridge between different sections of conduit. They ensure the safe and secure transmission of electrical wiring while protecting it from damage. In both residential and commercial settings, these connectors play a crucial role in maintaining the integrity of electrical installations. By providing a reliable connection, they help prevent issues such as short circuits and electrical fires. Understanding conduit connectors is vital for anyone involved in electrical projects, whether they are professionals or DIY enthusiasts. With various types available, choosing the right connector for your project is key to ensuring safety and functionality.

Types of Conduit Connectors

There are several types of conduit connectors, each designed for specific applications.

Standard Connectors are commonly used in dry environments where moisture isn’t a concern.

Flexible Connectors are ideal for areas that require movement or adjustment, allowing for easy installation in tight spaces.

Watertight Connectors provide excellent protection against moisture, making them suitable for outdoor or damp locations.

Threaded Connectors offer a secure fit by screwing into the conduit, ensuring stability even in challenging conditions. Understanding these types helps in selecting the appropriate connector based on the environment and requirements of your electrical project.

Materials Used in Conduit Connectors

Conduit connectors are made from various materials, each with its advantages and disadvantages.

Metal Connectors are known for their durability and strength, making them a popular choice for industrial applications. They can withstand harsh conditions but may be susceptible to corrosion over time.

Plastic Connectors, on the other hand, are lightweight and resistant to corrosion, making them ideal for residential projects. They are also more cost-effective, but may not offer the same level of protection as metal options.

When choosing materials, consider the specific needs of your project, including environmental factors and budget constraints.

How to Choose the Right Conduit Connector

Selecting the right conduit connector involves several key factors. First, consider the application of the connector. Is it for indoor or outdoor use? Outdoor applications often require watertight connectors for added protection.

Next, evaluate the environment where the connector will be installed. If it’s exposed to moisture or chemicals, opt for materials that can resist these elements.

Additionally, check the compatibility with the conduit type you’re using. Ensure the connector fits snugly and securely to prevent any electrical hazards.

Taking the time to assess these factors can lead to a safer and more efficient electrical installation.

Installation Process for Conduit Connectors

Installing conduit connectors correctly is crucial for the safety and reliability of your electrical system.

Step 1: Start by gathering all necessary tools and materials, including the connectors, conduit, and a suitable wrench.

Step 2: Cut the conduit to the desired length, ensuring clean, straight edges for a secure fit.

Step 3: Attach the connector to one end of the conduit. Make sure it is firmly seated, and tighten any screws or fasteners as needed.

Step 4: Connect the other end of the conduit to the appropriate outlet or junction box, ensuring all connections are secure.

Common Mistakes: Avoid over-tightening, which can damage the connector, and ensure you’re using the right type for your specific project.

Safety Considerations

Safety is paramount when working with electrical systems, including conduit connectors. Always follow safety protocols to minimize risks.

Before beginning any installation, turn off the power supply to the area. This reduces the risk of electric shock during installation.

Use insulated tools and wear protective gear, such as gloves and safety glasses, to protect yourself from potential hazards.

It’s also essential to ensure that all connectors are installed correctly. Poorly installed connectors can lead to overheating, short circuits, or even fires. Regular inspections can help catch any issues early, keeping your electrical system safe.

Maintaining and Inspecting Conduit Connectors

Regular maintenance and inspection of conduit connectors are vital for ensuring long-term functionality and safety.

Maintenance Tips: Keep connectors clean and free from debris. Inspect for signs of wear or damage, such as cracks or corrosion.

Regular Inspections: Schedule periodic checks, especially in outdoor or high-moisture environments. Look for any loose connections or signs of electrical arcing, which can indicate potential problems.

If you notice any issues, replace damaged connectors immediately to avoid compromising your electrical system’s integrity.

Taking these steps can help extend the life of your conduit connectors and enhance overall safety.

Conclusion

In conclusion, understanding conduit connectors is essential for anyone involved in electrical projects. By knowing the different types, materials, and installation processes, you can make informed decisions that ensure safety and functionality. Regular maintenance and inspections further enhance the longevity of these components. Always prioritize safety and follow guidelines to achieve the best results in your electrical installations.